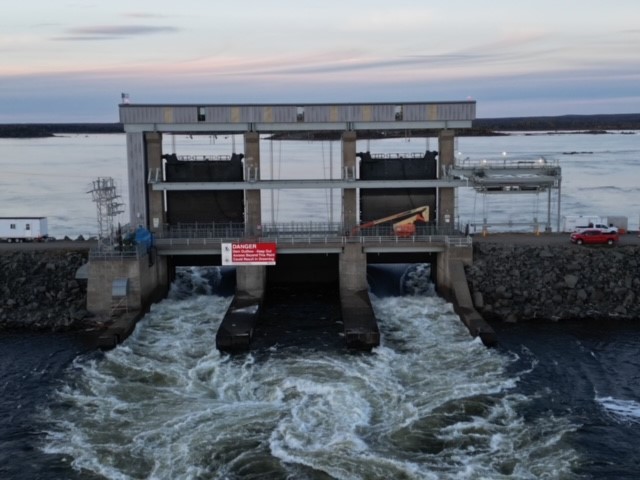

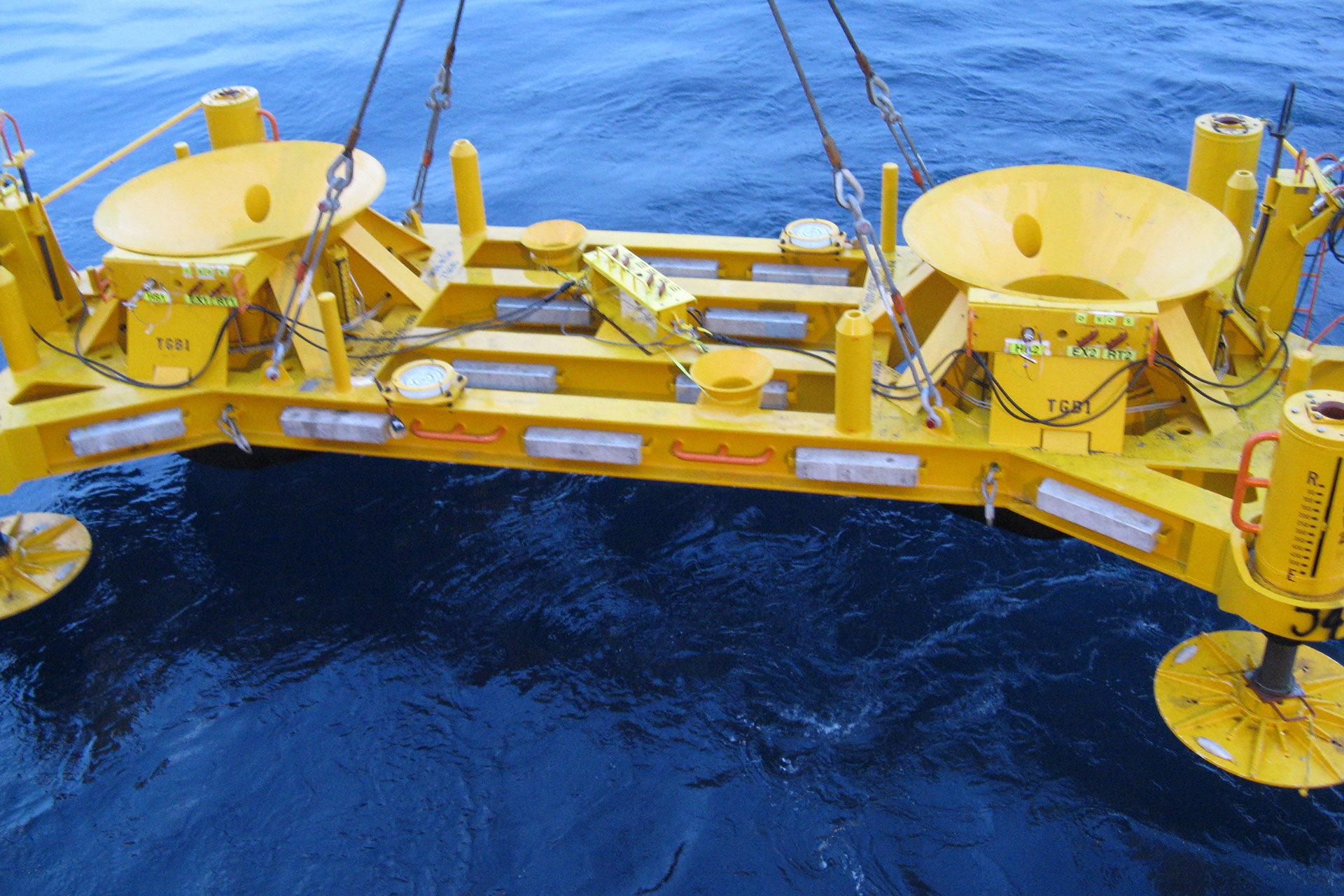

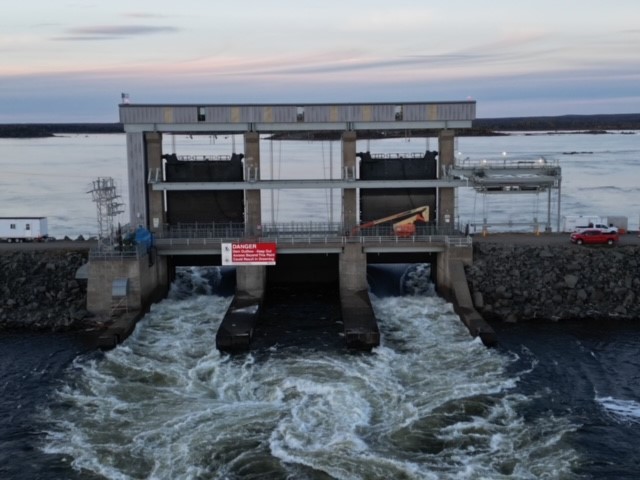

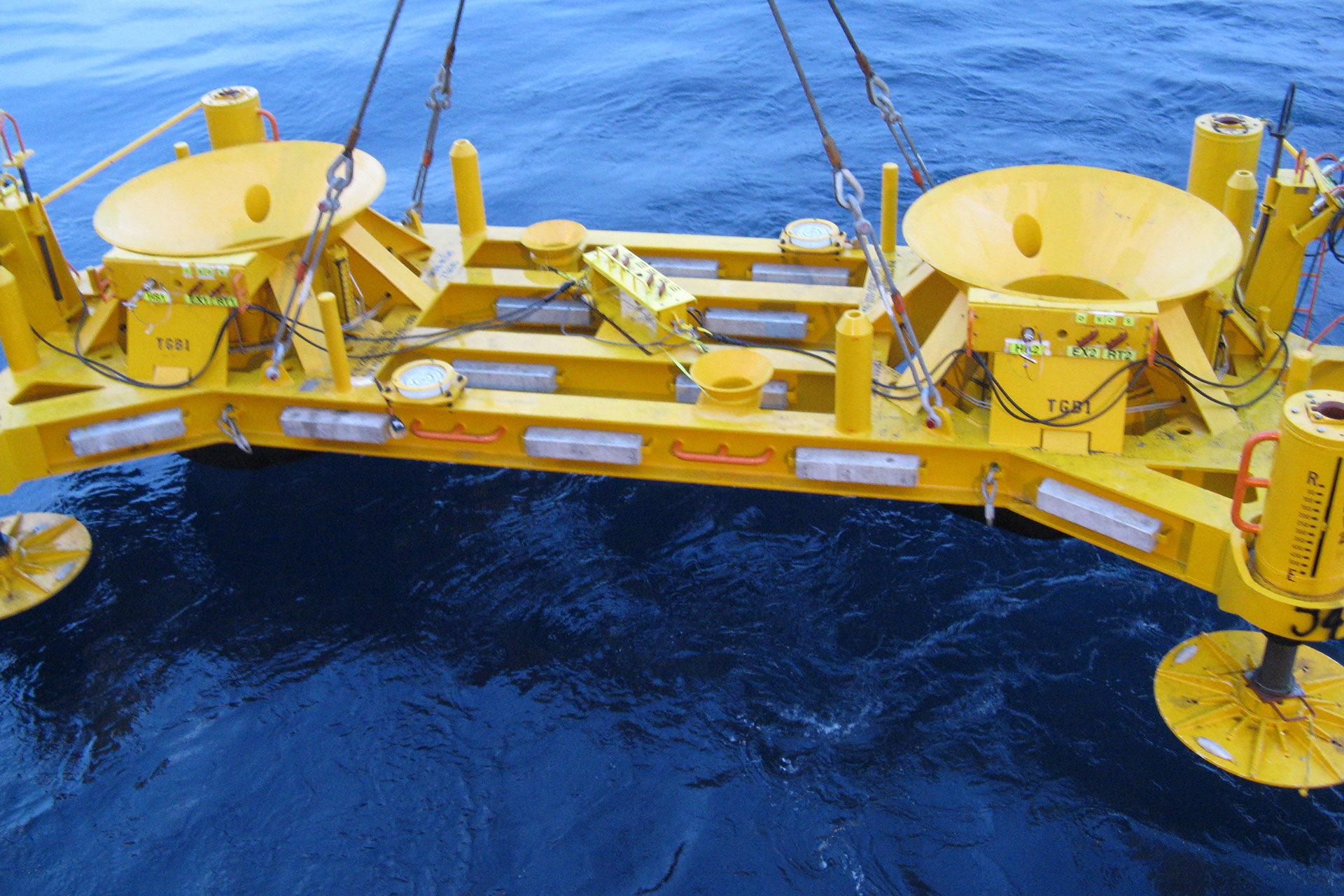

Terra Nova FPSO Refit & Maintenance

Client: Suncor

DF Barnes rapidly provided Quayside Services and skilled personnel, amassing 350,000-man hours over five months with impeccable safety. Versatile support extended offshore for Suncor's reconnection endeavors.

Learn More